WHEN THERE IS NO BEST SOLUTION, WE CREATE IT

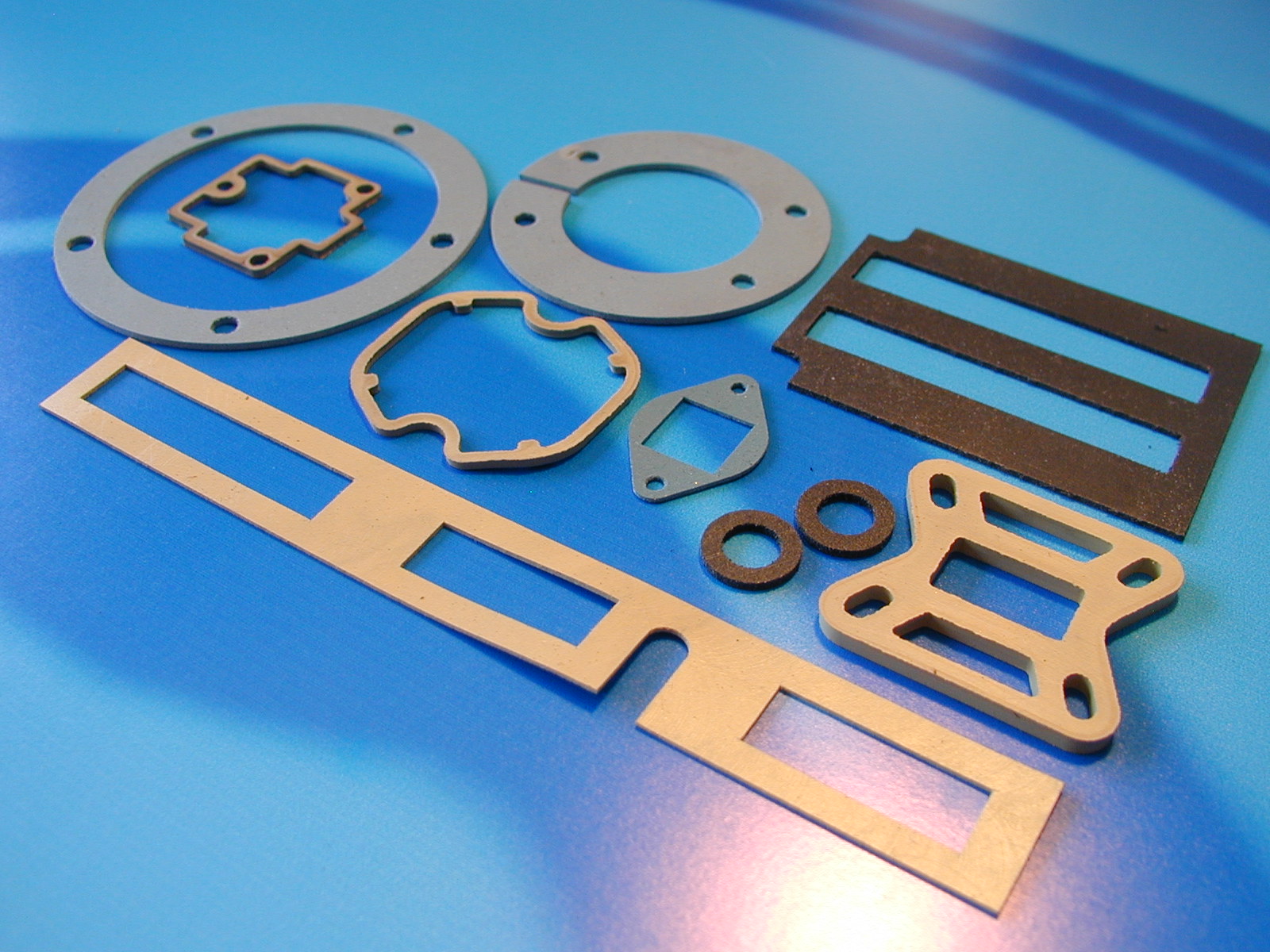

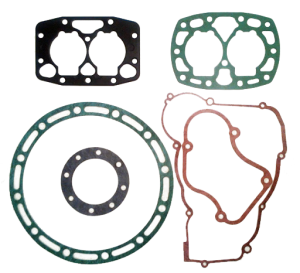

When standard gaskets are not able to meet particular needs, it is possible to opt for an ad hoc solution: custom-designed gaskets that are designed and manufactured to customer specifications. The design represents the fundamental phase: the identification of the dimensions and the material to be used must be as detailed and specific as possible.

There is no catalog of custom gaskets as they are manufactured specifically to meet customer specifications.

What to choose and when to change

UNIQUE PIECES

Special pieces made on specific customer designs can also be washers, orings, membranes, bellows, valves, cable glands, rubber-metal parts, special shapes, etc. with materials in various rubbers such as natural, nitrile, food, silicone etc.

SOME APPLICATIONS

Special seals are used in sectors such as plants or machinery, hydraulics, construction systems, engineering systems, gas springs, automation systems, transport systems, in the field of renewable energy, in the food and pharmaceutical industries.

FOR PROTOTYPING

Special seals are customer-specific sealing elements. Seals are often produced as a sample, a specially created design or design. The seals can also be adapted to the installation conditions and application parameters.

MATERIALS

Typical materials for these seals are NBR, FKM, EPDM, VMQ, FVMQ, HNBR, SBR, PTFE and TPU. In addition to the standard materials, there are also special materials available for low temperature applications, with special chemical resistance or very good compression set.